ISS MicroCoriolis Technology

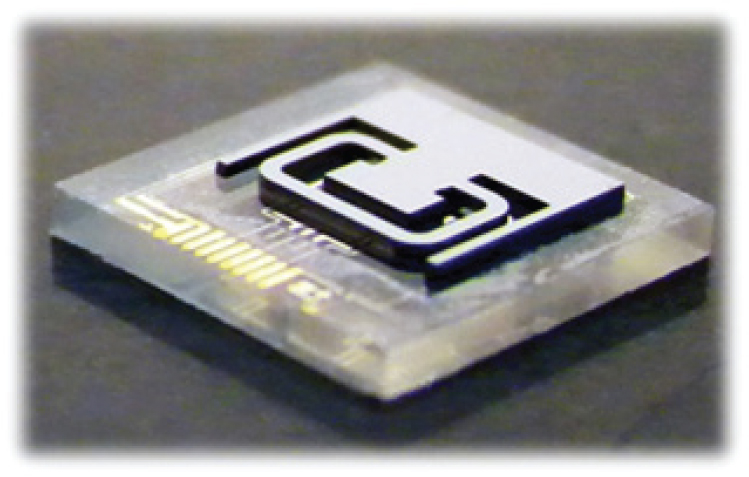

Silicon microCoriolis sensor

construction

Integrated Sensing Systems (ISS) has been a leader in Micro Electro Mechanical Systems (MEMS) since it’s founding in 1995. ISS developed fluidic MEMS technology as a tool for measuring the properties of fluids. Fluidic MEMS is a hollow resonant structure fabricated from silicon, which we call a micro Coriolis sensor. These sensors are fabricated using the combination of high volume silicon manufacturing technology, traditional Coriolis sensor design principles and advanced integrated electronics. ISS produces these sensors using an in-house MEMS fabrication facility. Processing signals based on the vibrational resonance of this structure are used to measure the fluid density, mass flow and viscosity. Silicon is an ideal fabrication material since it is 3 times lighter, is 3 times stronger and has 3 times the thermal conductivity of stainless steel. Silicon’s advantageous properties result in sensor that will revolutionize fluid measurement.

Gas Density Measurement

Gas density has traditionally been a challenge to measure using a vibrating structure. This was a result of trying to measure a small change in the resonant frequency of a heavy metal structure due to a small change in total mass of the system. The ISS Gas Density Meter sets a new standard in gas density measurement in terms of accuracy and stability. The microCoriolis silicon resonating structure is very light. A small change in gas density due to composition or pressure changes can easily be detected, even at atmospheric pressure.

Gas Concentration Measurement

Gas density is proportional to gas molecular weight, pressure and temperature. Small changes in pressure can have a great impact on gas density. When reporting gas density it is important to correlate it to a measured gas pressure. ISS includes an absolute pressure sensor with every gas density meter. Specific gravity, reference density and gas average molecular weight are calculated based on the measured density, temperature and pressure. Gas density can be used in place of other analytical technologies such as thermal conductivity and speed of sound measurements for concentration measurement. Here are examples of gas concentration measurements that can be accomplished using the ISS gas density meter.

- Correction of orifice flow volume measurements to changing gas density

- Conversion of gas volume measurement to mass measurement

- Heating value estimation of biogas

- Binary gas mixing control

Liquid Density Measurement

ISS has developed the worlds first microCoriolis liquid density meter. Liquid density is determined by measuring the frequency shift of a small silicon resonating structure due the weight of the liquid filling that structure. The result is a very accurate density measurement performance in a very small package. The high frequency resonance inherent in such a lightweight structure makes it immune to normal vibrations typically found in plant. This simplifies the installation of this meter in almost any environment. Installing a density meter now is as easy as installing a differential pressure transmitter.

An integrated temperature sensor is thermally connected to the fluid sensor. An external temperature probe interfaces with the meter to correct density,for example, to a flowing liquid temperature. For applications with widely varying pressures, a pressure sensor can be connected to the meter instead of a temperature sensor. Pressure measurement is used to correct the density measurement to provide the highest possible sensor accuracy.

Liquid Concentration Measurement

Liquid density measurement is a great indicator of composition of the fluid. The key requirement is the components must have pure fluid densities that are substantially different. Dissolved solids content in a liquid can also be determined using density measurement. When measuring small concentrations it is important to take into consideration the compressibility of the fluid. Fluids like alcohol have compressibilities over 100 parts per million per 15 psi of pressure. For measurements of trace water in ethanol compressibility should be taken into account. Here are examples of liquid concentration measurements that can be accomplished using the ISS liquid density meter.

- Ethanol concentration in water

- Salt concentration in water

- Sugar concentration (BRIX)

- Glycol concentration in water

Micro LDS

The Micro Liquid Density Sensors (LDS) was developed by ISS to satisfy the needs of the laboratory and process analytical market where an embedded liquid density can provide additional information about the fluid being measured. The micro Liquid Density Sensors (microLDS) use the same microCoriolis sensor technology found in the larger liquid density meter. This sensor also use a subset of the software found in the meter version. A version of the ISS Fluidic Communication Software can be used to interface with these sensors. These sensors are designed or general-purpose electrical environments.

Micro MCS

The Micro Methanol Concentration Sensor (MCS) was specifically designed to meet the need of the Direct Methanol Fuel Cell (DMFC) industry. Density and temperature is used to measure the methanol concentration used to feed the fuel cell. Methanol concentration is very important to measure for the correct operation of the fuel cell. The Micro MCS replaces the previous generation ISS FC10.

Viscosity Measurement

The ISS micro Coriolis sensor measures the viscosity of a liquid by analyzing the micro fluidic sensor vibration as it responds to fluids of different viscosities. Viscosity of the fluid dampens the vibration of the omega structure. The meter is calibrated at the factory with fluids of known viscosities. The internal volume of the sensor is only 200 nanoliters, making it the smallest viscometer on the market. Viscosity can be reported in dynamic or kinematic viscosity units using the integrated density measurement. Here are some examples of applications for the ISS liquid viscosity meter.

- Fuel viscosity for adulteration detection

- Injectable drug viscosity measurement

- Lube oil rheology – Milk viscosity

Mass Flow Measurement

The ability to measure very low liquid mass flowrates has been a challenge using Coriolis meters constructed from metal. ISS silicon microCoriolis mass flow sensors set a new standard for low flow mass measurement. The lightweight, strong, silicon fluidic MEMS structure responds to very small liquid mass flowrates. Mass flow is measured by detecting the twist in the omega structure as fluid flows through the meter. The ISS silicon mass flowmeter is a revolution in low flow measurement.

Here are examples of low mass flow applications for the ISS liquid mass flow meter.

- CVD liquid precursor flow

- Chemical research

- Low flow liquid flow metrology

- Low flow chemical dosing

- Medical fluid delivery

MicroCoriolis Measurement Capabilities

Liquid Density: 0.6 to 1.3 grams/cc

Temperature: -20 to 70C

Viscosity: 0 to 50 cP

Mass Flow: 0-1000 grams/hr

Gas Density: 0-30 kg/m3