Brix measurement that is rugged and reliable for wine quality monitoring

1 Sugar, the key to wine production

Density can be used to measure the sugar concentration (Brix) in grape juice or other fruit juice (must) prior to crush and throughout the fermentation process. Before grape or fruit harvest, the accuracy of sugar measurement in the juice is important in determining the timing of the harvest for the highest quality wine. During fermentation of the must, the sugar in the juice is converted into ethanol with carbon dioxide as a waste gas. Monitoring the density of the juice during this step in the process allows for optimal control of this conversion step for highest quality wines. Density (Brix) should be measured at least once per day during fermentation. Monitoring the slope of the Brix conversion slope allows the winemaker to adjust the temperature of the process for optimal wine quality.

2 Options for measuring sugar content

The primary measuring technologies used in measuring brix in the wine industry are the hydrometer and handheld density meters. These options are often subject to break easily if dropped or mishandled in any way due to the glass materials used in their construction. If the glass sensor tube of the handheld meter is broken then no measurements can be taken and a replacement meter will need acquired. Although very affordable, the hydrometer is difficult to read and is subject to the interpretation of each sampling technician. The hydrometer also requires a large volume for the sample and can be impractical for large wineries.

The Mobile Density Meter from Integrated Sensing Systems (ISSYS) provides winemakers with the option of performing density measurements in the cellar or in the lab. A few milliliters of sample are required for making the density measurement. There is no need for rinsing the density meter between samples when measuring wine. Yeast and dissolve CO2 in the wine will not affect the measurement. At the heart of the Mobile Density Meter is a patented, innovative MEMS vibrating density sensor that is immune to the effect of gas bubbles in the wine. This assures accurate and consistent measurements. Results are available in seconds.

The meter calculates sugar concentration based on measured density and temperature. Results can be displayed in the preferred units such as Specific Gravity or °Brix. Results can be stored in a file format that can be exported into applications such as Excel for further analysis.

The Mobile Density Meter features a small carrying case that houses the liquid density measuring sensor. The meter is connected to USB port on a Windows 7 or 8 devices for power and display. Once a sample is inserted to the sample port the display will provide an immediate reading.

3 Case study: On tank fermentation monitor

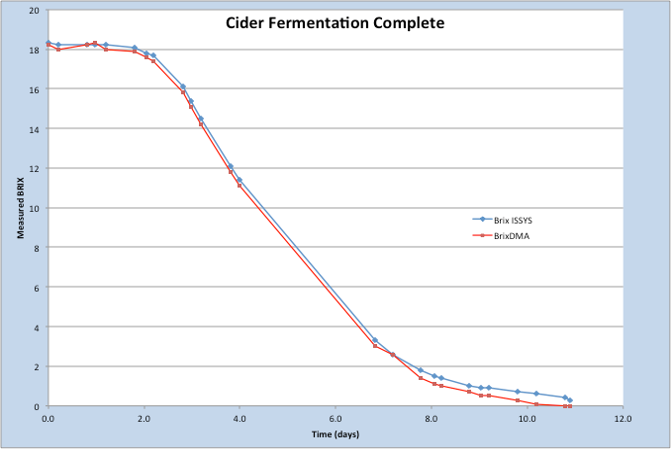

The same ISSYS liquid density sensor was used at a hard cider plant. The hard cider maker tested the sensor in an on-tank solution for monitoring Brix during multiple fermentation runs. This simple test was performed using data comparisons for each sample taken from 2 different instruments; the hand held digital density meter (DMA) vs the ISSYS liquid density meter on-tank fermentation monitor.

The results of the test showed that bubbles in cider did not affect the ability of ISSYS sensor to accurately determine BRIX, yeast did not affect ISSYS sensor, and the Brix measurement from both instruments were in line.